Why Choose Pemberton Engineering?

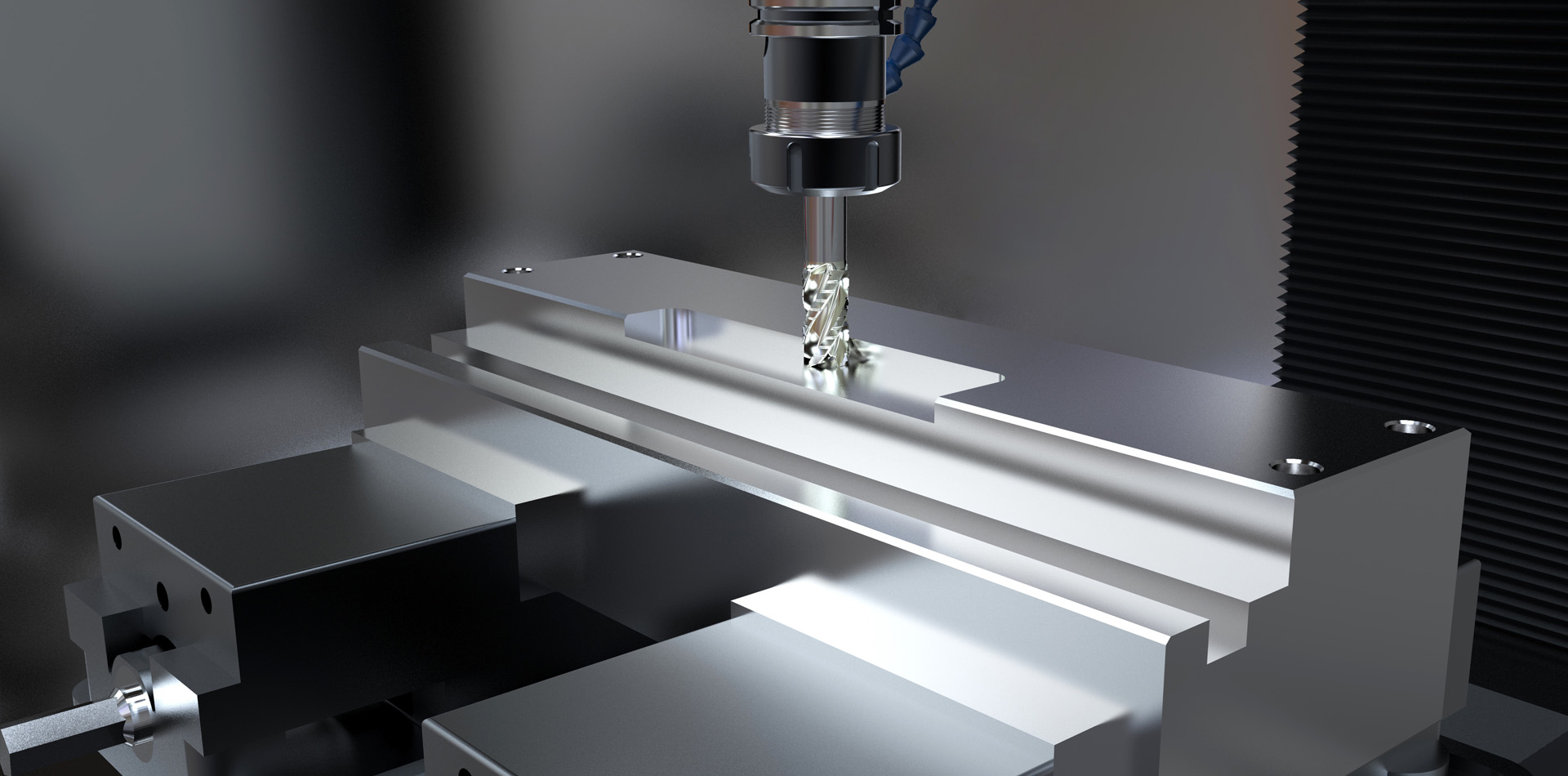

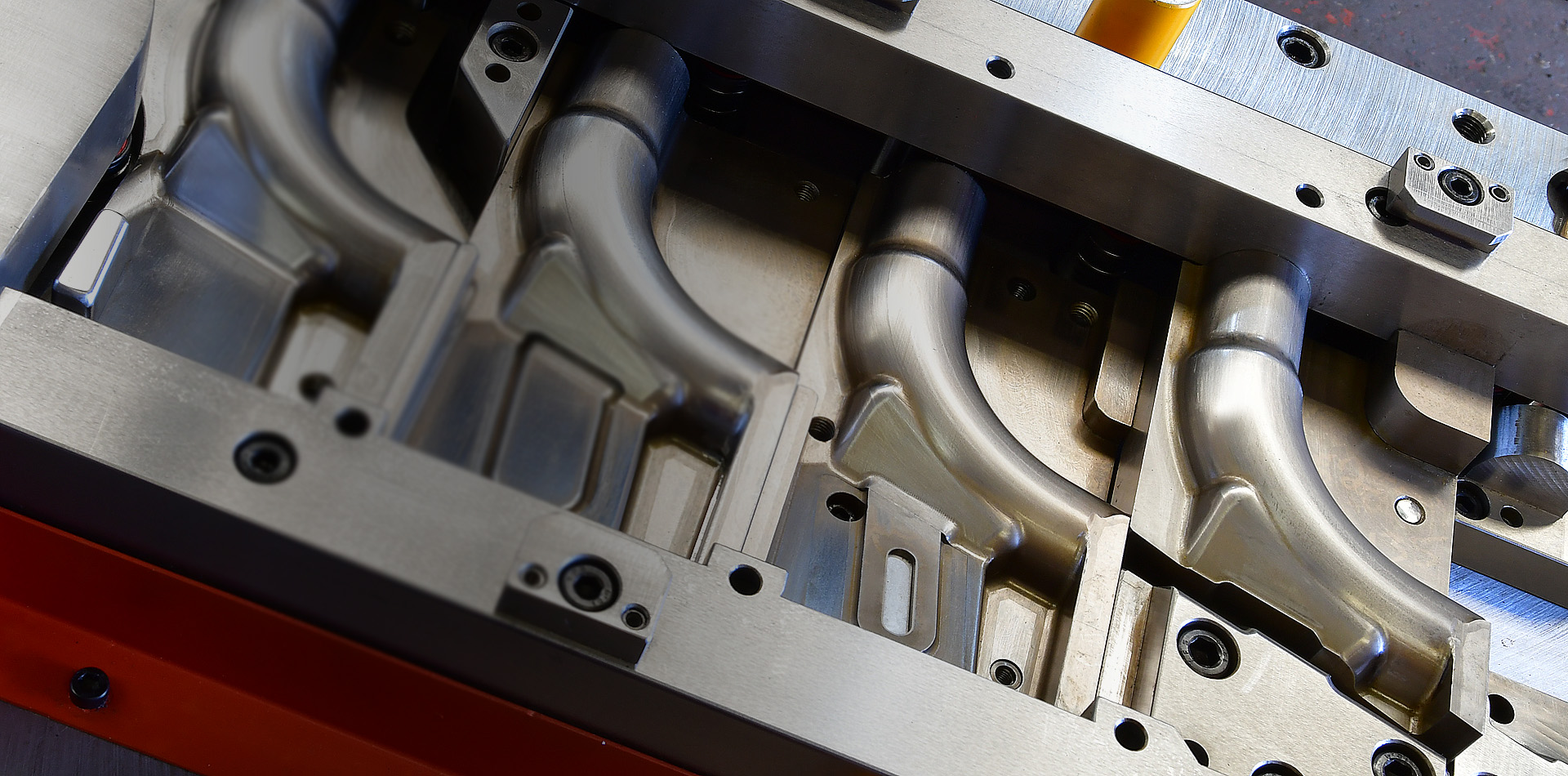

Pemberton Engineering has been manufacturing press tools, jigs and fixtures for over 35 years. Producing tools for a variety of industries, in recent years this has centred around the strong automotive growth sector. The company has a wealth of experience and has a policy of training apprentices to be part of our skilled workforce of the future. We are constantly re-investing in machinery, people and facilities in order to maintain the high quality of manufactured tools and services we offer our customers.

Lead times and a prompt repair service are high priorities for us, as our customers demand that products arrive on time and can be assured of an attentive and prompt service back-up. Our vast experience allows us to highlight possible problems when tooling is designed, speeding up the manufacturing process and mitigating for flawed designs. We have a wealth of experience in all aspects of press tool design and manufacture, working with a multitude of materials from brass and aluminium through to much stronger tensile properties of 550MC and similar.

Click here to read more >>